We Bring Back the Sparkle in Your Smile.

From Chairs to Clouds: How 3D Printing & AI are Revolutionizing California's Dental Practices

Language :

Topics:

For decades, a dentist's world was shaped by putty, plaster, and the patience for a two-week mailer to a lab. In California, at the epicenter of global technological innovation, this world is undergoing a radical transformation. Digital dentistry, once a niche curiosity, is now a fundamental shift, with 3D printing and AI-powered CAD/CAM systems leading a revolution in precision, efficiency, and patient care. If your practice is still guided by traditional methods, it's easy to view these technologies as expensive gadgets for early adopters. The data, however, tells a different story: these tools are reshaping the competitive landscape. As a recent analysis notes, this is not about following trends, but examining the "measurable differences... to determine if and where digital dentistry offers genuine advantages"

The shift is particularly pronounced here in California. Driven by major industry leaders, pioneering Dental Support Organizations (DSOs), and a culture that embraces innovation, the state is a hotbed for the development and adoption of these technologies

. From Los Angeles to the Bay Area, forward-thinking clinics are leveraging this tech to not just improve outcomes, but to fundamentally reinvent their service models and economic potential.

The Core of the Revolution: Precision, Speed & Expanded Services

The promise of digital dentistry rests on a powerful trifecta of benefits that directly address the limitations of analog workflows.

-

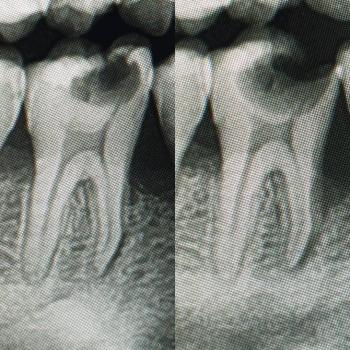

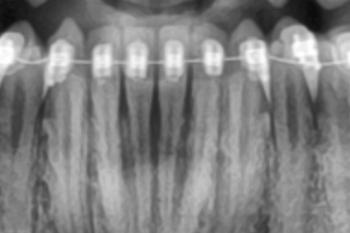

Unmatched Accuracy & Consistency: The shift from physical impressions to digital scans eliminates the variables of material setting, distortion, and human technique

. Modern intraoral scanners capture precise 3D data in minutes, and 3D printers fabricate models, surgical guides, and restorations with sub-50 micron accuracy. This "scan-to-print" chain creates a digital thread of accuracy that minimizes adjustments, reduces remake rates by up to 18%, and delivers a perfectly fitting product every time

-

Dramatic Time Compression: The traditional multi-visit, multi-week timeline for a crown is becoming obsolete. With a chairside CAD/CAM system, what once took two weeks can now be completed in under two hours

- . Digital workflows cut total treatment time by an average of over 60%. This efficiency isn't just about speed; it's about capacity. Practices report workflow capacity increases of up to 50%, allowing them to see more patients without compromising quality

-

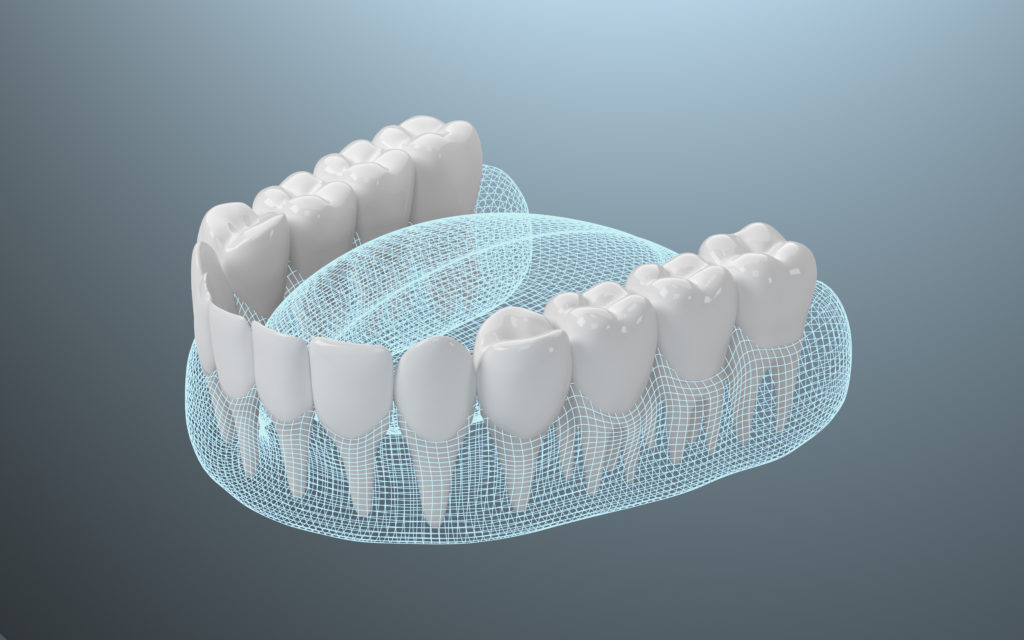

Service Portfolio Expansion: This is where the business model transforms. In-house 3D printing enables services that were previously impractical or outsourced:

-

Same-Day Provisionals & Surgical Guides: Print accurate temporaries and implant guides while the patient is in the chair, elevating your surgical and restorative planning

-

-

Clear Aligner Therapy Support: Participate in the orthodontics boom by producing in-house models for clear aligner cases, from start to finish

-

Custom Appliances: Efficiently produce night guards, occlusal splints, and detailed diagnostic models, turning what was a lab service into a profitable in-office procedure

The AI Catalyst: From Tool to Colleague

The latest wave of innovation infuses Artificial Intelligence directly into the digital workflow, moving beyond fabrication into intelligent assistance

| AI Application | Function & Benefit | Impact on Practice |

|---|---|---|

| Automated Image Analysis |

| AI algorithms review X-rays and CBCT scans to flag cavities, bone loss, and anatomy with 80-92% sensitivity, serving as a consistent second pair of eyes. | Enhances diagnostic confidence, aids in early intervention, and improves patient communication. |

| AI-Assisted CAD Design |

| Software suggests optimal margin lines, occlusal schemes, and connector sizes for crowns/bridges, reducing design time by up to 60%. | Saves 30-45 minutes per restoration case, standardizes quality, and reduces reliance on technician skill level alone. |

| Predictive Analytics |

| Models combine scan data with patient habits (e.g., smoking, hygiene) to forecast caries risk, periodontal disease progression, or aligner tracking issues. | Enables truly preventive, personalized care plans and improves long-term treatment outcomes. |

A Real-World Blueprint for the Transitioning Dentist

Adopting this technology is a strategic journey, not a single purchase. For the established dentist, a phased, educated approach is key to success.

-

Start with the Digital Gateway: The Intraoral Scanner. This is the foundational piece. It replaces messy impressions, which 89% of patients prefer

-

. Start by using it for "scan-and-send" cases to trusted labs to build comfort. This step alone improves accuracy and patient experience dramatically.

-

Integrate In-House Production with a 3D Printer. Once comfortable with digital scans, introduce a dental-specific 3D printer. Begin with high-volume, low-risk applications like surgical guides, models, and night guards

-

. This demonstrates immediate ROI by bringing lab work in-house and creates a foundation for more complex work.

-

Embrace AI and Advanced CAD/CAM. With a digital workflow established, leverage AI tools for diagnostics and design. Consider a milling machine or high-resolution printer for definitive restorations. This stage unlocks true same-day dentistry and positions your practice at the cutting edge.

-

Invest Heavily in Education. The greatest barrier is not cost, but the "skill gap"

- . As the Institute of Digital Dentistry emphasizes, the "true potential is realized through the skilled hands and minds of well-trained practitioners". Dedicate time and resources to certified training for you and your team. Many DSOs and equipment vendors offer robust educational pathways

The California Context: A Market Primed for Innovation

California isn't just adopting these trends; it's accelerating them. The state's large DSO presence helps practices negotiate costs and access training. Its aging population drives demand for efficient prosthodontic solutions that digital workflows excel at providing. Furthermore, patient expectations here are shaped by tech culture; they anticipate precision, speed, and a seamless experience—all hallmarks of digital care.

The advice is clear: digital dentistry, particularly 3D printing and AI-driven CAD/CAM, has moved past the realm of early adopters. It represents the new standard of efficient, precise, and patient-centered care. For the California dentist, the question is no longer if to transition, but how strategically to do so. Begin with a scanner, commit to learning, and expand your capabilities step-by-step. The future of your practice—and the quality of care you can provide—will be built layer by digital layer.